PRODUCTION MANAGEMENT SOFTWARE FOR THE FOOD INDUSTRY

VERINOX CUMIXNET SOFTWARE

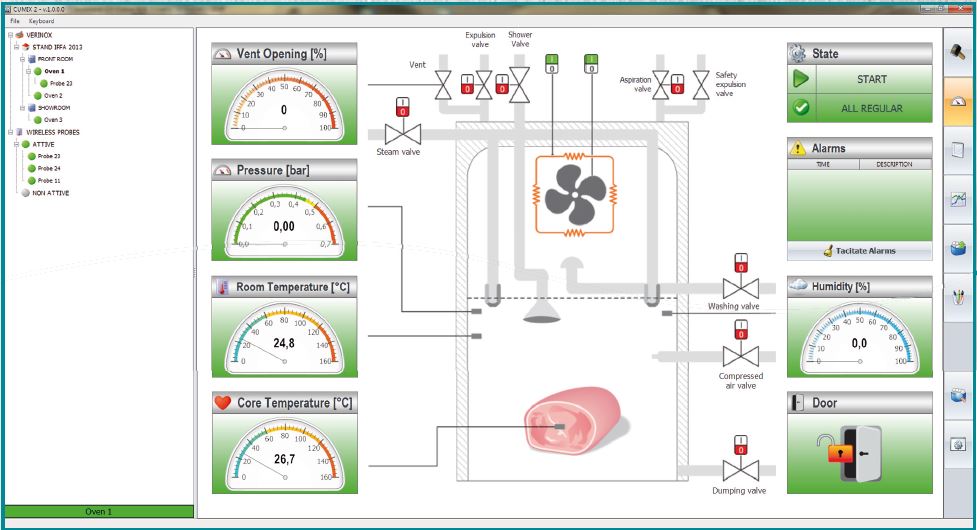

We have developed a new generation software for plant centralization, enabling the automated management of industrial production in the food sector.

CUMIXNET PRO2 software can be applied to any industrial food plant to control production processes. More specifically, this system allows to monitor production plants, analyse processes and intervene both on site and remotely.

MANAGEMENT SOFTWARE FUNCTIONALITY

MAXIMUM VERSATILITY

Thanks to its flexibility, all your production plants can be controlled with a single system, regardless of the manufacturer.

You can therefore monitor ovens, stoves, seasoning cells, cold rooms, refrigeration systems, churns, air conditioning systems, pasteurizers.

PROCESS TRACEABILITY

The probes of the systems can be monitored, along with the analysis and comparison of the different traces. This system also allows to keep track of and archive process records, associating production codes.

RECORDING OF EVENTS AND OPERATIONS

The Black Box integrated into the management system allows you to review each process step made by the plant or by the operator. Furthermore, messages sent out regarding command, alarm or status can be filtered by category or production code.

RECORDING RECIPES

All production recipes are stored for automatic production execution. In addition to archiving, the software allows the transfer of recipes to other software to facilitate in cases of multiple production plants or factories.

REMOTE ASSISTANCE AND CONTROL

You can monitor your system online (Internet or Intranet) and intervene on the processes in real time. Updates can also be carried out remotely, with continuous support from our remote assistance.

Test the system with us in our laboratory to see the CUMIXNET PRO2 software applied to your new plant in action.